SPH-01 fuelling station both for mines and surface

SPH-01 Fuelling station both for mines and surface

automatic device usable also for underground coal mines

ATEX certification

connectable to the DPS11 system

Advantages of the fuelling station:

Economic fuel saving

Precision records of the fuelling into working machines, e.g. locomotives

Engine adjustment troubleshooting thanks to purposeful consumption records

Operator-friendly operation

Automatic records of fuelling operators

The fuelling can be carried out also manually without pressure air

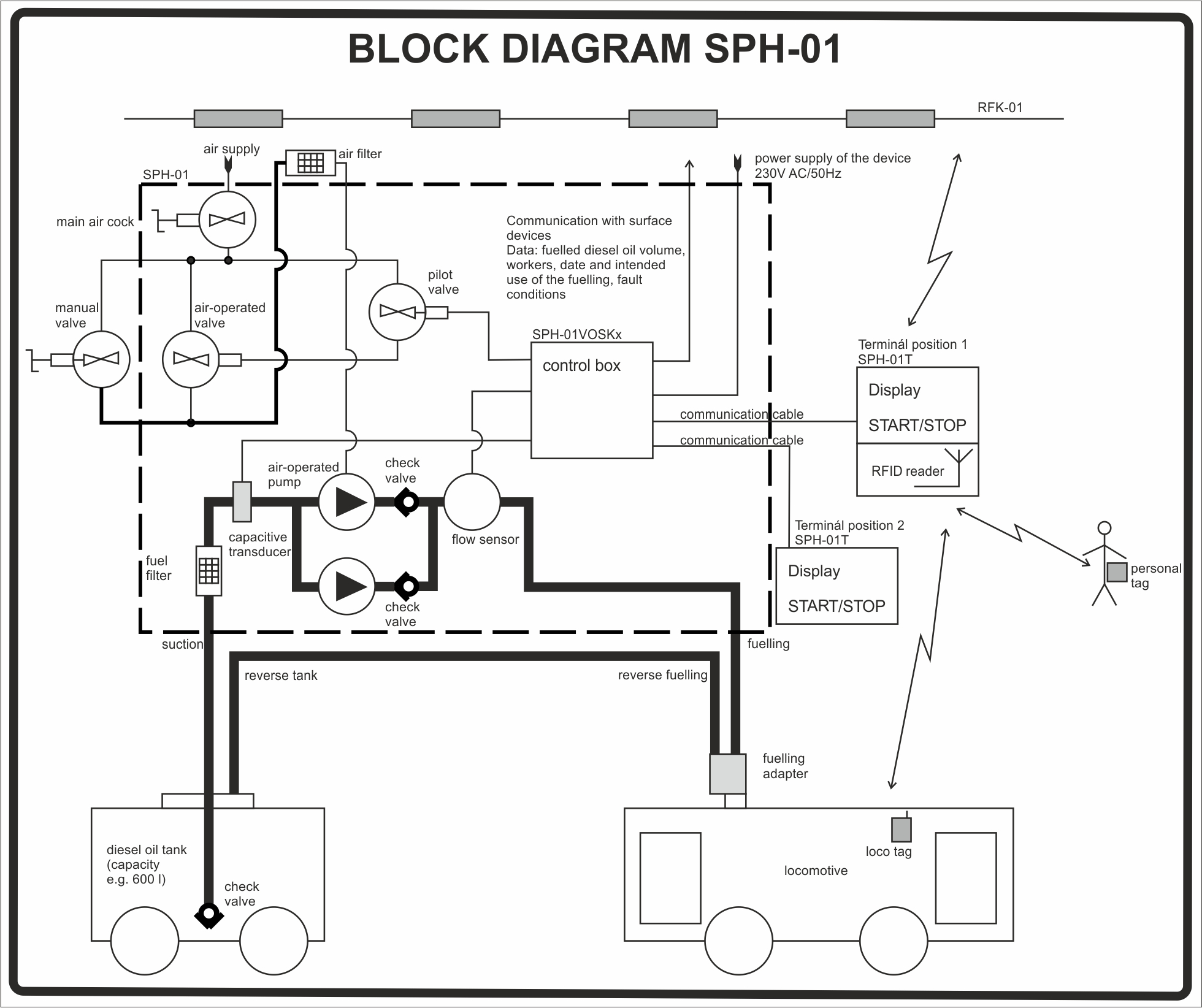

The SPH-01 serves as a system for fuelling the diesel oil, identification of users, recording their operations and transferring data to superior workers for recording, filing and evaluating. Other media can be fuelled as well.

SPH-01 stores data about operations of workers, such as installations of new fuel storage tanks, fuelling into specific working machines equipped also with identification devices or recording free fuel consumptions (e.g. into fuel canisters for remote working machines).

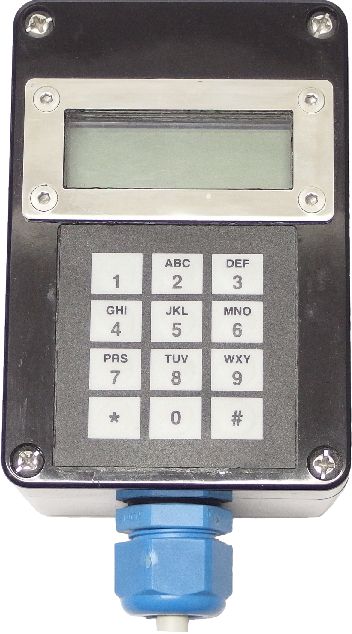

The device is controlled entirely through the SPH-01T terminal. Two terminals can be connected to the SPH-01 device.

Basic parameters for applications:

- the pumped medium is diesel oil (also other petroleum products if agreed with the manufacturer)

- fuelled volume manually 0.23 l/r or automatically 0.25 l/sec

- operating temperature -20°C to +40°C

- weight approx. 120 kg

- pressure in the air distribution system min. 2.8 bar – max. 6.0 bar

- SPH-01 unit in IP 54 and SPH-01T terminal in IP 65

- communication with active worker and machine ident. tags (ISI) in the band of 863 MHz – 868 MHz

- variant power supply 230 V AC / 100 mA or 24 V DC / 300 mA

The delivery of the SPH-01 fuelling station contains:

- SPH-01 complete unit

- Two SPH-01T terminals

- Original user manual in the language of the country of use

- Declaration of ATEX conformity

- The fuelling can be carried out also manually without pressure air